Partnership for peak performance.

Aftermarket support, technical training, financing, and safety programs designed to maximize uptime, efficiency, and ROI.

Global parts and field service

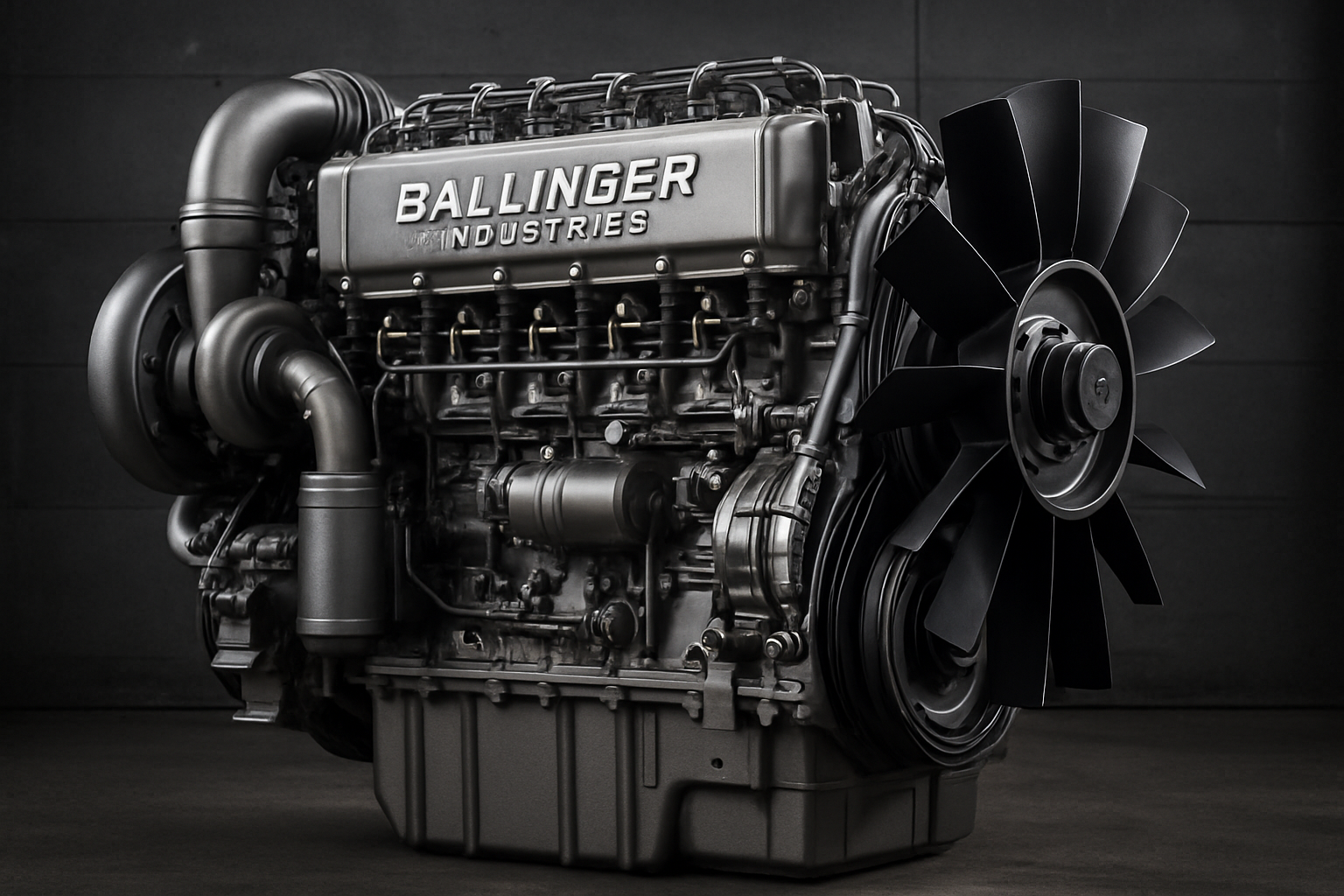

Genuine Ballinger parts, certified technicians, and predictive maintenance keep every machine operating at peak potential.

Genuine Parts

OEM-spec components with rapid logistics from regional depots.

Field Service

Certified technicians with advanced diagnostics available 24/7.

Predictive Maintenance

Telematics-driven alerts for proactive component replacements.

Warranty Management

Clear coverage, streamlined claims, and engineering feedback.

Planned uptime for every fleet

Preventive and predictive programs align with your utilization and project timelines.

- Preventive plans: Scheduled services with parts kits and technician visits.

- Predictive plans: Oil sampling, vibration analysis, and telematics alerts.

- Component rebuilds: Undercarriage, hydraulics, and powertrain exchange options.

Operator and maintenance certification

Hands-on training ensures operators, maintenance teams, and fleet managers maximize safety and productivity.

Operator Certification

Ergonomics, visibility, advanced controls, and safe operation best practices.

Maintenance Training

Diagnostics, repair, preventive maintenance, and hydraulic/electrical systems.

Digital Learning

Online modules, video tutorials, and certification renewals for distributed teams.

Real-time insight for uptime

Connected machines deliver diagnostics, utilization data, and geofencing for safety and productivity.

- Predictive alerts for filters, fluids, and component wear

- Geo-fencing and curfews to protect assets on remote sites

- Fuel and idle reporting to reduce total cost of ownership

- APIs to integrate with fleet management platforms

Flexible programs tailored to projects

Leases, loans, and trade-in programs that align with project timelines and budget cycles.

- Customized Leases: Operating and capital leases aligned to your utilization plans.

- Competitive Loans: Attractive rates and flexible repayment for new and used equipment.

- Trade-In Programs: Streamlined upgrade paths to the latest Ballinger technology.

Zero-harm commitment

Safety is embedded in machine design, operator training, and site procedures.

Safety Engineering

ROPS/FOPS cabins, 360° visibility, fall protection anchor points, and redundant braking systems.

Compliance Support

Guidance on OSHA requirements, lockout/tagout, and regional emissions standards.

Site Programs

Daily safety briefs, PPE compliance, and on-site audits to sustain a zero-harm culture.