Forging the future of infrastructure.

A legacy of American engineering excellence, driven by innovation, safety, and unwavering commitment to our partners.

Built in Findlay, Ohio since 1995

Ballinger Industries, Inc. was established in 1995 in Findlay, Ohio with a clear mission: build the most durable and reliable heavy machinery in the world. Our first bulldozer line quickly earned a reputation for unmatched performance across the Midwest’s rugged terrains.

Over the past three decades, we expanded into advanced lifting, paving, and specialized forestry equipment while preserving our core values of integrity and innovation. Today, Ballinger machines operate on construction sites, mines, ports, and infrastructure projects across North America and beyond.

1995: Founded in Findlay

Launch of heavy-duty bulldozers built with American steel and operator-first controls.

2005: Lifting & paving expansion

Introduced all-terrain cranes and smart screed pavers for highway and runway work.

2015: Telematics & predictive maintenance

Deployed remote diagnostics and predictive maintenance across the fleet.

2024+: Hybrid & zero-emission access

Hybrid-electric AWP platforms for dense urban and indoor job sites.

Vision, mission, and values

American-built machines that set the benchmark for reliability, safety, and sustainability.

Vision

To be the global partner of choice for infrastructure development, recognized for engineering excellence and machines that endure.

Mission

Design, manufacture, and support high-performance heavy equipment that maximizes productivity, enhances safety, and advances sustainable growth.

Integrity

Operate with honesty, transparency, and ethical rigor in every engagement.

Innovation

Invest in R&D for telematics, automation, and efficient powertrains.

Durability

Engineer components to withstand extreme conditions and maximize uptime.

Safety

Prioritize operator well-being through visibility, ergonomics, and advanced safety systems.

Executive team

Decades of experience in heavy machinery manufacturing, engineering, and global operations.

Elias Ballinger

Chief Executive Officer

Founder and mechanical engineer guiding product quality, customer partnerships, and American manufacturing investment.

Dr. Anya Sharma

Chief Technology Officer

Leads R&D across telematics, automation, and sustainable power solutions for heavy equipment.

Marcus “Mac” Allen

Chief Operating Officer

Oversees production, supply chain, and quality systems within our 450,000 sq ft Findlay facility.

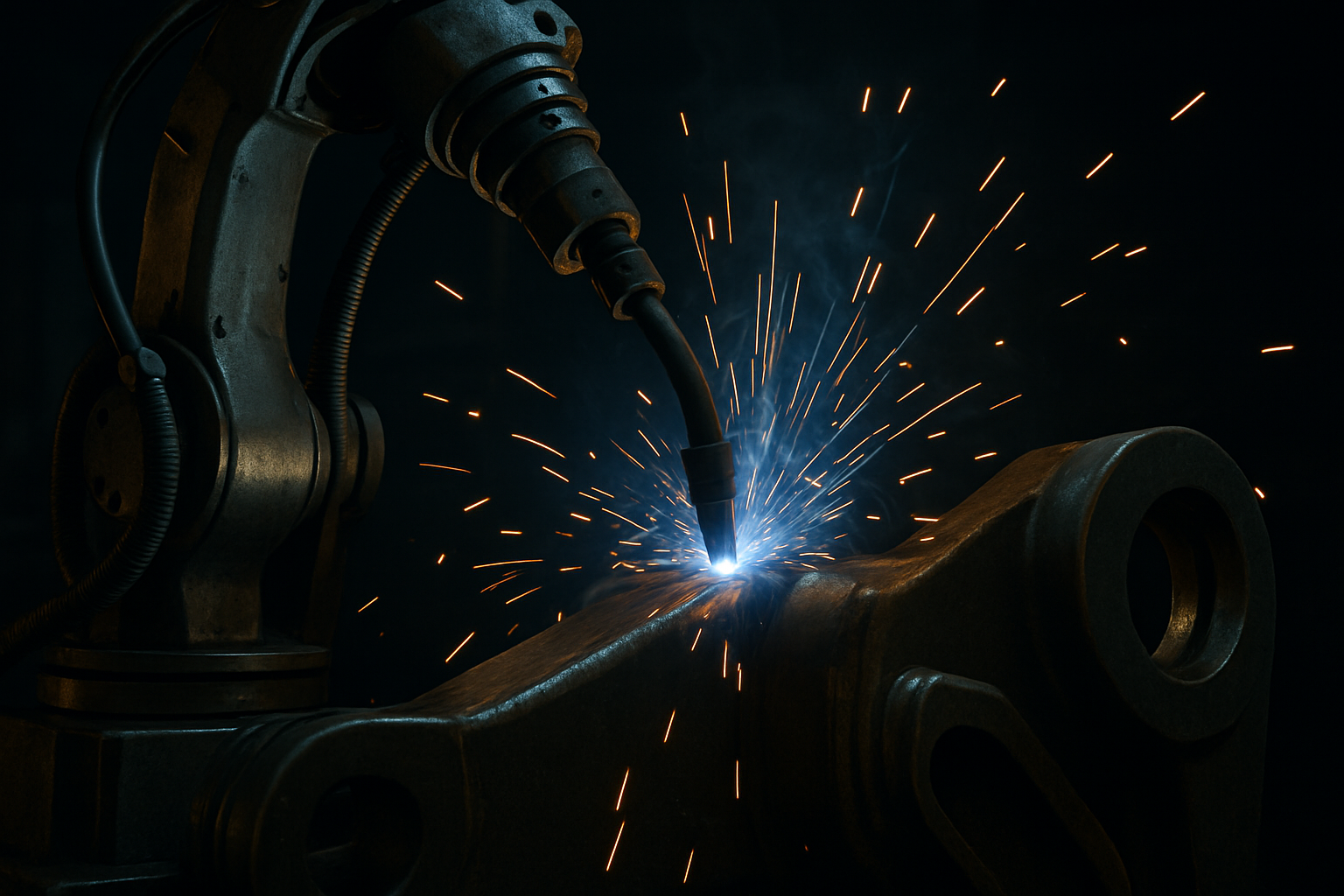

450,000 sq ft vertically integrated facility

Laser cutting, heavy weld, paint, final assembly, and test tracks operate under ISO 9001 with continuous improvement programs. Operator-in-the-loop validation ensures comfort, visibility, and safety are baked into every design.

- Telematics-enabled QA and torque traceability

- Endurance testing for hydraulics and powertrains

- Supplier quality audits and PPAP processes

- Robust parts logistics for global support

People-first, safety-first

Training, apprenticeships, and leadership development keep our teams growing with the technology we build.

Career paths

Engineering, operations, supply chain, and field support roles with mentorship and certification programs.

Explore CareersSafety culture

Zero-harm commitment with daily safety briefs, PPE compliance, and continual training for every station and job site.

See Training